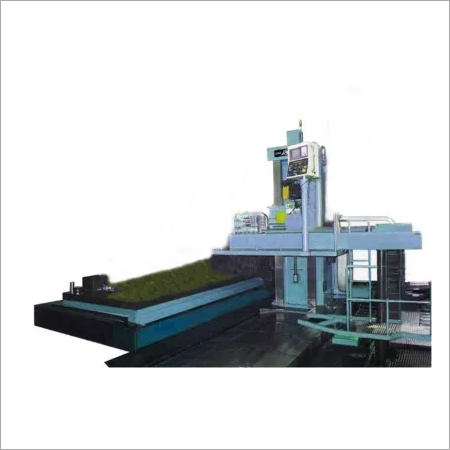

Deep Hole Drilling Machine

2500000 INR/Unit

Product Details:

- Spindle Speed 1,2,3,4, and 6 mm/m

- Product Type Drilling Machine

- Material Metal

- Automatic Grade Automatic

- Capacity 22 T/hr

- Color Grey

- Click to view more

X

Deep Hole Drilling Machine Price And Quantity

- 1 Unit

- 2000000.00 - 10000000.00 INR/Unit

- 2500000 INR/Unit

Deep Hole Drilling Machine Product Specifications

- Grey

- Automatic

- Metal

- Drilling Machine

- 1,2,3,4, and 6 mm/m

- 22 T/hr

Deep Hole Drilling Machine Trade Information

- 20 Unit Per Month

- 2 Months

- All India

Product Description

Deep Hole Driller Machine is used in special machine building, transfer lines as an independently-operating machine. This is used in automobile, aviation, medical and general mechanical engineering sectors for creating deep holes. It is available with 1-,2-,3-,4-, or 6-spindles in compact design and ingenious module system. It guarantees high productivity and drilling accurateness with enormous ease of operation.

Features of Deep Hole Drilling Machine:

Features of Deep Hole Drilling Machine:

- Drill spindle drive having frequency-controlled drive.

- Feed by frequency-controlled servo-drive having encoder.

- Feed spindle is designed as backlash-free recirculating ball-screw.

- Drill spindle ensures lubrication with high precision.

- Tool failure safety devices to ensure to provide the best possible tool protection.

- Strongly connecting rigid welded structure.

- Compact construction with short times for retooling.

- Precihole introduces a new range of heavy duty XY BTA Drilling Machines serving the range from Dia. 12.7mm to 50.8mm drilling and up to 750mm deep.

- These machines serve components weighing up to 22 Tons.

- The machines are moving column type and have CNC controls to control accuracy and precision.

- The Company also offers custom solutions to suit your requirements.

- Tooling and work holding are provided to suit your component.

- Professional Installation, Training, Documentation and Process engineering are all provided by Precihole to successfully adapt the machine at customer site.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Call Me Free

Call Me Free

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese